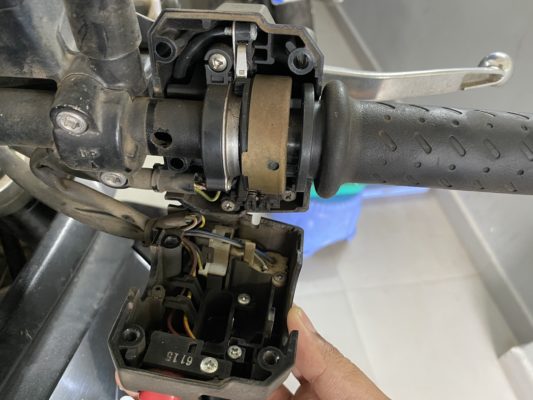

Ride by wire technology is actually quite a contradiction. But goes well with many other concepts of the automotive industry. Here the absence of a mechanical linkage or a throttle\accelerator cable between accelerator and the throttle. That is the whole point. But how it works is by a sensor that the accelerator has which conveys information to the throttle body by wires. Confusing right.!!!! Imagine I had to sit and find a simplified way to put it to you guys. This technology was pioneered by Yamaha, “Yes Yamaha”, back in 2006 on the R6. Unfortunately for Indians, Yamaha’s big bikes are far from our shores.

Ride by wire helps in controlling air-fuel mixture, that was the main purpose but has led to many other advantages too. With emission norms becoming more and more strict, many manufacturers are not only having this in bigger more expensive bikes but in beginners and commuter bikes too.

In older Carbureted motorcycles, depending on the twist of the accelerator the cable would get pulled which would lead the throttle body to open the slider on the carburetor to help the inflow of air for a air\fuel mixture. Working towards better combustion and emission norms fine tuning was getting difficult.

With Ride by wire the sensor detects the position of the accelerator and sends information to the actuator, that helps change position of the throttle that is sent by the ECM that decides how much air flow is required depending on the requirement. Earlier air\fuel mixture was the Sole purpose for this tech but coming to the present day where sensors rule the automotive industry, this has given rise to many more advantages.

Let’s mention some:

- The primary advantage is that like a cable, the sensor doesn’t make the twist of the accelerator hard in the due course of time.

- Less chances of the sensor giving up than a Cable snapping due to age.

- You can have riding modes. ( rain, road, sport) giving diff throttle inputs.

- Traction control is another advantage where-in if the sensor feels the loss of traction it lessens or cuts off throttle input.

All these are not only helping in reducing rider inputs thus causing less stress and in many cases also saves lives.

There are also a few disadvantages but I am nitpicking.

- If the sensor gets spoiled or malfunctions the only way to get it fixed is by changing it by sending the bike to the respective service outlets. Whereas in a cabled throttle it can be changed by you with the right tools.

- Ride by wire sensor is expensive to manufacture and is also expensive to replace. The cable is relatively quite cheap.

So there you have it guys a small peek into the world of ride by wire technology or throttle by wire.

Check the full video on Youtube: https://youtu.be/7UHhmvj7xN8